According to the United Nations (UN), 26.4% of the world population have been affected by moderate or severe food insecurity in 2018; more than 800 million people in the developing world suffer from chronic undernutrition. Although the food produced globally can feed the whole world’s population, the problem lies in the enormous amount of food loss and waste, in addition to the very unequal distribution of food. One-third (1.3 billion tons) of all the food produced is either lost or wasted.

Global efforts have begun as early as 1978, when the Food and Agriculture Organization (FAO) established the Action Programme for the Prevention of Food Losses in 1978, which ran until the early 1990s. Then, Zero Hunger has come second of the 17 UN Sustainable Development Goals-named in 2015-to serve as an international call for action.

Food Loss vs Food Waste

To better view the problem, it is important to differentiate between food loss and food waste. Lost food, on the one hand, is the food that spoils before reaching the retail markets or the final consumer. Food loss indicates problems in food production processes, policies, or markets. Wasted food, on the other hand, refers to the food that retailers and/or consumers throw away. It is more of a behavioral problem that has to do with our habits, often taking place during gatherings and ceremonies, as well as in restaurants and hotel settings.

Needless to say, food losses are more common in developing countries while food waste is more pronounced in developed ones. According to Thomas Colin Campbell Center for Nutrition Studies, the United Kingdom wastes 32% of purchased food (about 6.7 million tons), whereas in Africa, 25% to 50% of food is lost right after harvest. Now, let us focus on losses that occur along the food supply chain, and how to address them.

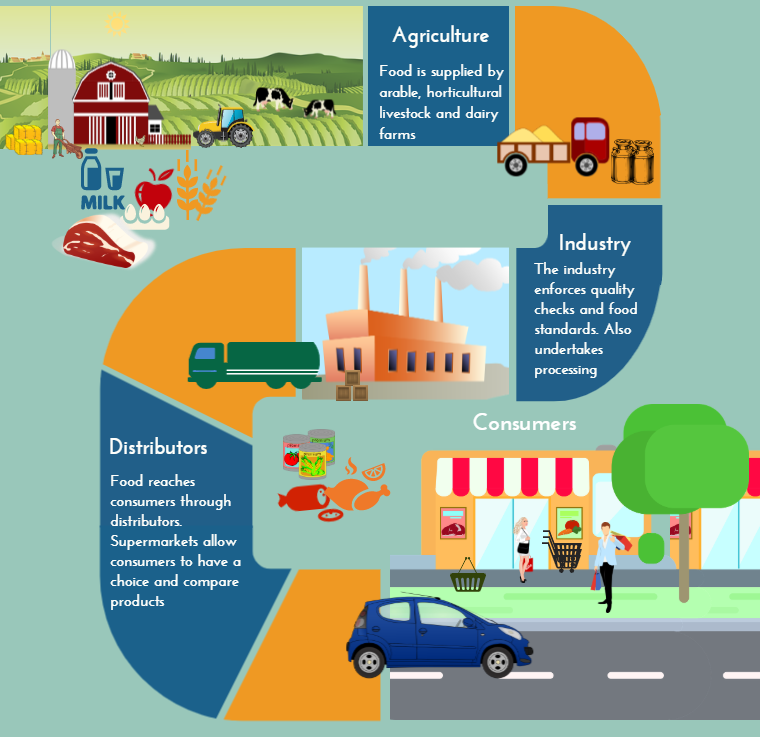

Food Supply Chain. Source: cdn-wordpress-info.futurelearn.com

Food Supply Chains

A supply chain refers to an entire system of operations, people, and organizations involved in transporting a product from the place where it is made to the final customer. Although each product or service has its own unique sequence of supply chain, a typical one would include the following actors: the input supplier, the producer, the distributer, the wholesaler, the retailer, and the final costumer. These actors perform different processes such as storage, processing, transportation, packaging, etc.

As such, the food supply chain refers to how food is transported from farms to end up on ours plates, including the different stages, actors, and processes that food goes through along this journey. We can distinguish two types of food supply chains; one for fresh products as fruits and vegetables, and the other for processed ones such as canned and packed foods and dairy products.

The first stage of a typical food supply chain is production, where the actors are farmers, and the processes include planting seeds, irrigation, fertilization, pest control and harvest. Then comes the post-harvest stage, where farmworkers work on packing and loading crops in preparation for transportation. The third stage is transportation, where carriers and agents transport food products either to wholesale markets, or factories for further processing, or exporters facilities. Afterwards, food products are transported again from these stations to the retail markets, and eventually reach the final consumer.

Post-Harvest Losses

In general, post-harvest losses correlate to inefficient management of supply chains. Technological advancements play a key role in minimizing the losses, and that is why most losses occur in the less-advanced countries. Now, let us view two examples of food loss across the supply chain.

Grains are considered the most durable-or non-perishable-crops, compared to tubers, fruits, and vegetables. They include cereals and legumes, and constitute a major food source. Wheat, rice, and maize alone contribute more than half of all calories consumed by human beings.

Storage is a key stage in the grain crops supply chain as they often require storing for long periods. Around 15% of the global grains production is lost mainly due to inefficient storage at poorly constructed granaries. In poorer regions, they can be even stored in farmers’ houses under unfavorable conditions, leading to huge losses. Grains can also be lost to physical spillage during handling and transportation. In developed countries, non-perishable crops losses are very low.

Things are quite different for perishable horticultural crops, such as fruits and vegetables. Although the loss rate is higher in both developed and developing countries, it occurs due to different reasons. For example, failing to meet cosmetic or quality criteria set by importers and retailers would cause a percentage of losses in the developed countries. About 10% only of fruits and vegetables are lost between farm and retail market in the UK.

On the other hand, according to the UN, up to 50% of fruits and vegetables produced in developing countries are lost at early stages of the supply chain. These losses occur for diverse reasons, including applying primitive harvest techniques that may bruise fruits, the lack of efficient packing houses, transportation without transit packaging, and the lack of temperature-controlled supply chains, the cold chains.

Minimizing the Loss

Minimizing lost food is directly linked to designing more efficient supply chains. This could range from procedures as simple as gentler handling of products, to full-digitally-controlled supply chains.

It all starts at the field, where modern technologies can be utilized to monitor crops and predict the best harvest time according to the purpose; be it exportation or direct selling to wholesalers. One such technology is the system developed by the Egyptian scientist Nashwa El-Bendary; the system won the UNESCO–ALECSO Award for creativity and technical innovation for young researchers in the Arab World 2014, and the L’Oréal-UNESCO “For Women in Science” Levant & Egypt fellowship 2015.

Other than that, utilizing temperature-controlled storage and transportation facilities can preserve food for significantly longer periods. Some advanced cold-chain containers can be controlled remotely to monitor temperature and humidity levels. However, according to the Global Cold Chain Alliance, less than 10% of all perishable foods in the world are refrigerated while moved across the supply chain.

Moreover, an efficient food chain would track supply and demand data, to prevent over production and the potential resulting losses. Advanced chains allow different players to monitor this data digitally to act accordingly and take prompt actions to avoid spoilage of products.

It is worth mentioning that Egypt has launched a huge ambitious project known as “The National Project of Grain Silos” a few years ago, which entailed the construction of 50 silos in 17 Egyptian Governorates, with a storage capacity of

1.5 million tons. The silos are fully controlled using the latest technologies. They are operated by well-trained staff to maintain optimum storing conditions and precisely control the inputs and outputs according to demand. According to statements of a highly-ranked governmental official, the project has saved over one million tons of grains annually, which is equal to one-tenth of the country’s annual consumption.

Another significant model to highlight is what is known as a closed-loop supply chain. In such a model, potential losses of a certain supply chain are fed back into another chain to capture its value. For example, misshapen products are directed for processed food facilities, inedible parts are directed for other industrial applications, while unavoidable losses can be directed to the bio-energy sector, and so on and so forth.

Image by Freepik

Image by Freepik

Minimizing the Waste

On a side note, let me talk briefly about decreasing food waste-which you my dear reader can directly take part in and give you some invaluable tips.

- It all starts at shopping. Prepare a list of your actual needs before shopping, buy rational quantities of fragile food products, and do not give in to offers.

- Never throw away food. Preserve food from going bad through proper storage and preservation techniques; regularly check your fridge; and turn your leftovers into new meals. Also, note that irregular shaped fruits and vegetables are as delicious and nourishing as regular shaped ones.

- If you live in the countryside, or in a house with a garden or backyard, think of home-based biogas units, which can turn organic wastes into free clean energy.

- Serve smaller portions in plates, and refill if you need more. Also, a better way of welcoming your guests would be frequent offering of small portions instead of forcing big portions on their plates.

- Last but not least, always remember that sharing is caring, and give food you will not consume or recycle to the needy.

Decreasing food loss and waste does not only imply increased food supplies to the world, but also carries lots of other benefits. Think of the virtual values involved in food production; human labor, water footprint, carbon footprint, and land use. Actors and stakeholders involved in the chain would benefit financially as well. Farmers would not lose income on food they could not sell, and transporters would not waste the fuel used for transporting food that spoils as it travels. Enhancing food supply chains is indeed the key to turn an urgent crisis into a promising opportunity.

References

americanexpress.com

civilsdaily.com

fao.org

gcca.org

nutritionstudies.org

sdgs.un.org

sis.gov.eg

Ghamrawy, M. 2019. Food loss and waste and value chains – Learning guide. Cairo, FAO.

Julian Parfitt, Mark Barthel and Sarah Macnaughton, 2010. Food waste within food supply chains: quantification and potential for change to 2050 Phil. Trans. R. Soc. B3653065–3081

Further Reading

Egyptian Scientists, Nashwa El-Bendary

Food Science and Food Conservation (Autumn 2015 Issue: Food and Agriculture)

Food Waste and World Hunger (Summer 2019 Issue: SDGs)

Food Scarcity vs. Distribution (Summer 2019 Issue: SDGs)

The Taste of Culture (Winter 2014: Human Civilization)

Two Birds, One Stone

This article was first published in print in SCIplanet, Winter/Spring 2021 issue.

Cover Image by wirestock on Freepik.